What is Supply Chain Traceability?

Supply chain traceability refers to the ability to track and trace the journey of products from the initial stage of raw material sourcing through production, processing, and distribution, until they reach the end consumer.

It involves capturing and recording data at each step of the supply chain, ensuring transparency and enabling stakeholders to verify the origin, handling, movement, and quality of products.

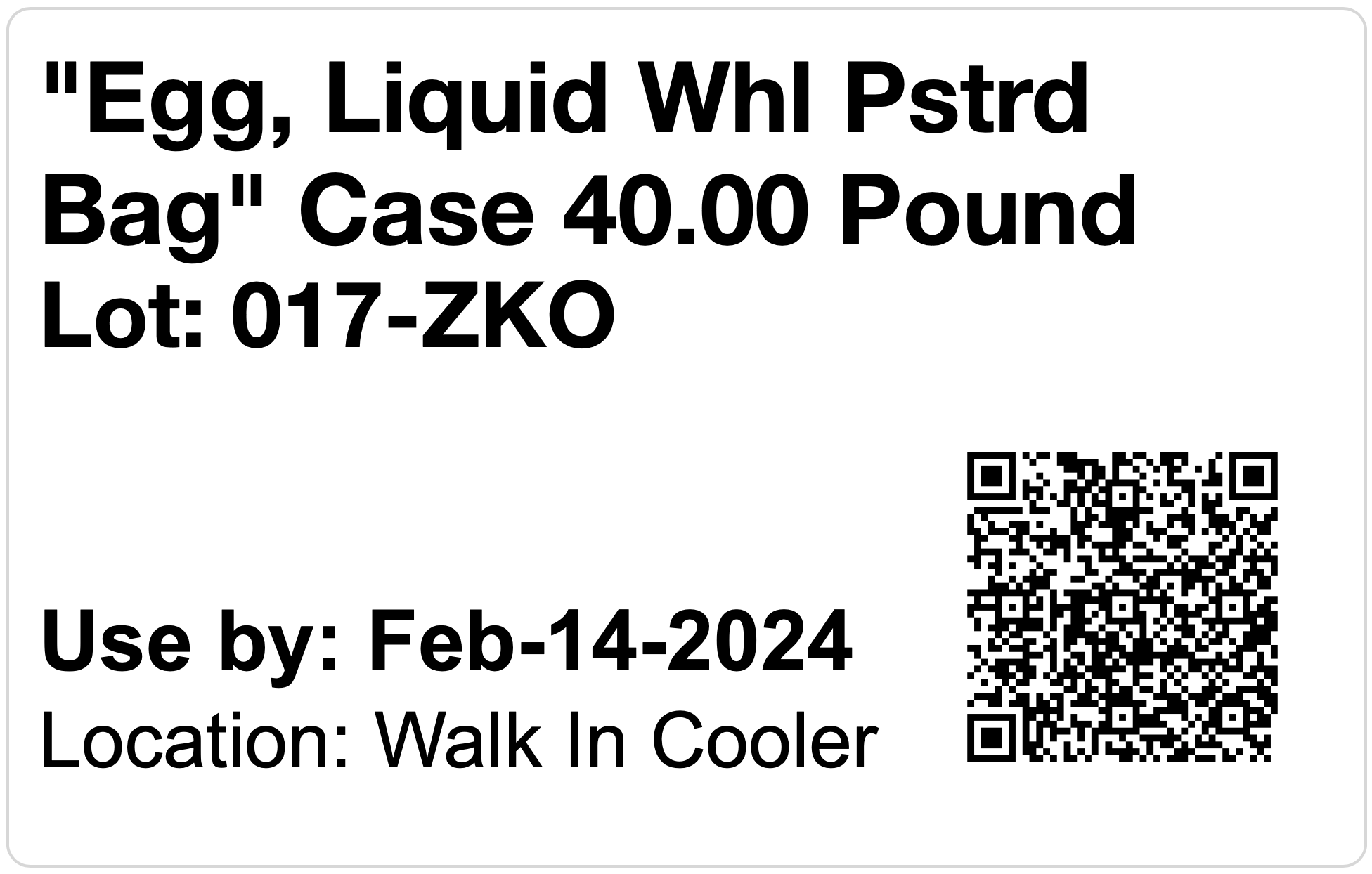

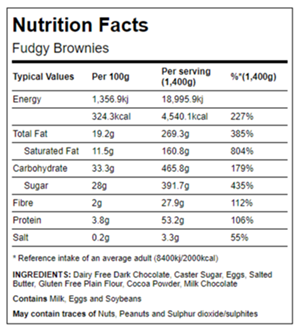

Accurate data needs to be collected at every step of the supply chain.

- Raw material sources

- Manufacturing processes

- Storage conditions

- Transportation

Streamline Bakery Software is an advanced software solution used to facilitate traceability.