Program reports according to your production logic

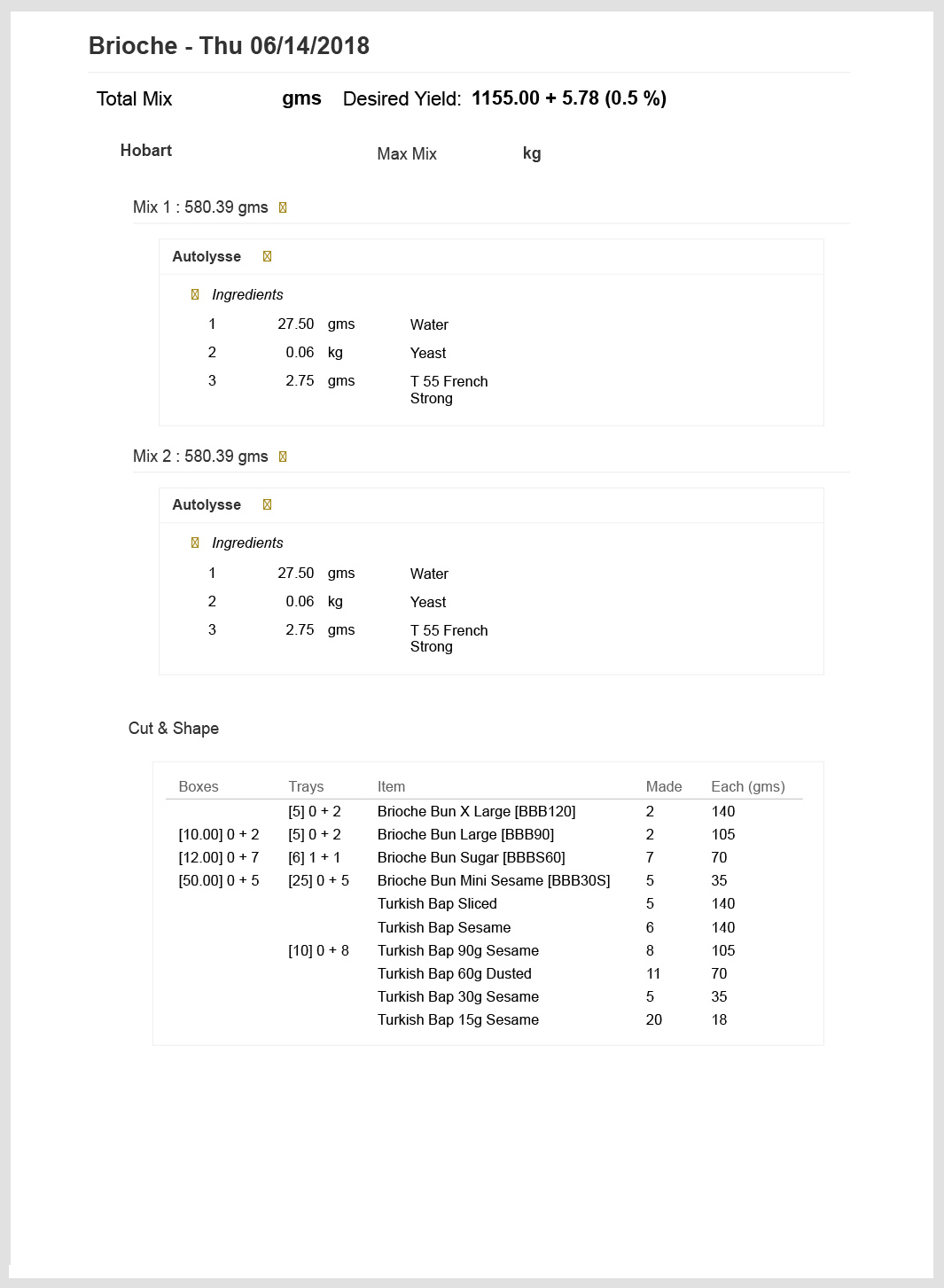

Recipe Cards

Recipe cards are automatically created according to orders.

Recipes are split in various mixes, depending on the capacity of the machine used.

For example, if the total needed is 300kg and the maximum capacity is 200kg, then the recipe will be broken down into 2 mixes, giving the option to mix two equal ones or one at the maximum capacity of 200kg and one at the balance of 100kg, or there is third option to manually enter each desired mix.

You may also set the total yield to be a percentage higher than that called for by the recipe.

Production Planning: Inventory Items

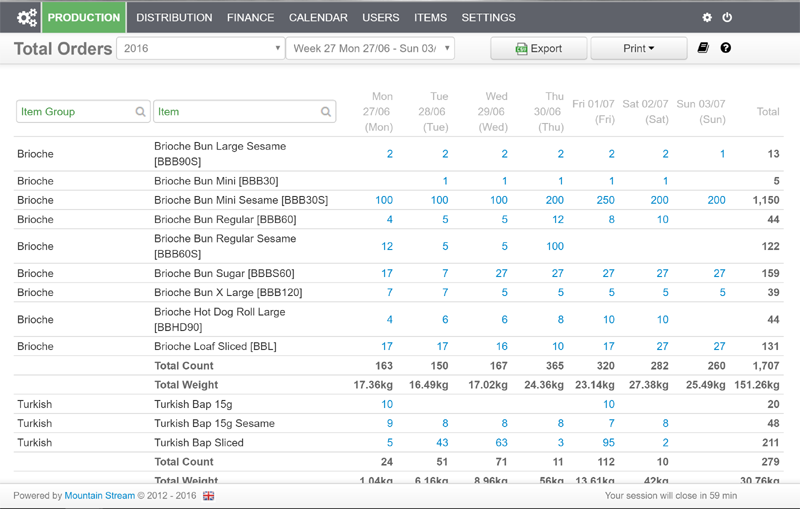

Plan production at a glance – view all required information to make decisions:

- Total quantity on order

- Current stock

- Balance needed

- Suggested amount to make

- Maximum stock limit

- Shelf life

- Filter each recipe line by date range and save settings.

- Adjust suggested production figures and click and drag to production.

- View planner by day or week

Unlimited Production Reports

Our database structure allows you to easily and quickly create ANY report needed.

Standard reports:

- Recipe Cards

- Cut & Shape

- Slicing

- Bagging

- Labels

- Ingredients used

- Stock levels

- Shopping lists

- Total weekly orders

- Orders by item

- Orders by customer

Report filters:

- Date range

- Production shift

- Production line

- Weigh station

- Delivery route

- Delivery date

- Production date

- etc – (Unlimited)

Trays, Trolleys & Decks

Streamline calculates the number of trays and decks needed to bake a batch.

Production reports show the total number of pieces as well the individual weight of each item.

Production Reporting: Features & Settings

Custom Reporting

Format and customize production reports to

suit your needs:

Organize production reports to follow your

production logic: item groups and item lines

appear in the order needed.

- Hide/show columns and rows

- Set column widths

- Set font size for print

- Save custom settings

Production times (turnaround times)

Production Times

An item’s production time is the time needed from order deadline to delivery, as follows:

| Production Time | Delivery |

| 0 | Next day |

| 1 | After 24 hours |

| 2 | After 48 hours, etc |

Delivery Date vs Production Date

Example:

A sourdough baguette may be produced over 24 hours as it requires time to ferment the dough. The production time = 1.

A brioche, on the other hand, is available for next day delivery. The production time = 0.

Streamline reports by production shift and by delivery date.

Production reports respect an item’s production time. Late orders are highlighted to illustrate the changes.